Oil cargo discharge operation involves various safety factors to be taken into consideration.

The following are the most common elements and check items to be developed. The procedures explained here are only indicative, not exhaustive and one must always be guided by the practices of good seamanship.

Supply of I.G to cargo tanks being discharged:

Confirm that the I.G.'s main supply's oxygen level is less than 5% & supplied to tanks.

The date, time, voyage number and description of operation should be entered on the IGS fixed pressure and oxygen density recorder.

Line up of the IGS::

- Before starting of discharge, IGS must be set appropriately to maintain a Positive Gas pressure in all tanks at all times.

- Cargo tanks I.G. inlet lines to the designated discharging tanks shall be re-checked and confirmed in the desired position.

- The control of the key to the locking arrangements for cargo tank I.G. inlet valves shall be with the Chief Officer.

- For tanks which are required to be isolated by vapor (as per the Charterer's instructions), the individual I.G. pressure shall be monitored Every 4 hrs.

Preventing for Cargo Contamination including Vapor Contamination

Standard Oil Tankers except Product Oil Carriers are provided Single Main Inert Gas and Common Vent Lines, connected with all cargo oil tanks.

In such vessels, I.G. Inlet (Cut-out) valves should be operated, if the Charterer requests to prevent Vapor contamination, which may be restricted to monitor the mainline pressure, to require to fit portable pressure gauges for cargo oil tanks which are isolated.

Also, in a Product Oil Carrier, below precautions should be considered to prevent Cargo contamination.

- Vapor contamination at the exhaust end in a Slop tank of AUS Vacuum Pump.

- Liquid contamination with leakage of valves of Manifold Vapor Equal Line.

- Liquid contamination with leakage of Manifold Drain Line.

Safety Confirmations and Clearance:

Once Chief Officer is satisfied that all preparations made following the cargo oil discharge plan and the shore facility representative have confirmed that the facility is ready to receive cargo, he may order the designated manifold valve to be opened, the I.G. output to the discharging cargo tanks and the discharge operations to commence following the discharge plan.

Commence discharging at reduced speed. Follow shore instructions & Increase the discharge rate once it has been confirmed that no oil leaks and shore are receiving at their end until the agreed cargo oil manifold pressure has been reached.

Deck Watch and Personnel Arrangement

The deck watch shall check for oil leaks in the cargo area throughout the cargo oil discharge operation.

At the beginning of the operations, confirm that no oil leaks from piping joints and that no oil inflowing into tanks other than the tank being used.

Continue monitoring of the Oil Level from the discharging tanks, until settling down of cargo pumps and flow rate.

It has occurred in the past that, due to excessive shore back pressure & height level of shore tanks, causing filling of ship's tanks and subsequent overflow, due to inadequate monitoring.

After reaching the desired full rate with all the required cargo pumps and confirmation reports have been received from all stations at deck / pump room watch, (including the cargo piping, pumps and sea surface around the vessel) the Chief Officer may dismiss the off duty crew and revert to the routine Watch Schedule

During discharging operations, watch manifold pressure all the time, and monitor portions where oil is likely to leak.

Starting of Discharge Operation pumps and adjusting Internal Pressure of Tanks

Open manifold valves, and start the first cargo pump at slow speed.

After confirming the regular operation of each part, open delivery valves to start pumping oil. Then start other pumps.

Only after receiving reports of all safety checks confirmed from all stations of deck/pump room watch, then follow the instruction of the terminal side to increase the manifold pressure to the prescribed (agreed) pressure.

A close watch of the manifold pressure shall be maintained until completion of the setting down of shore-side / ship's cargo pumps.

When starting pump flows, pressures and flow of cargoes are to be maintained at a minimum. Only on confirmation from the receiving terminal and completion of results from safety check at each designated (staffed location) should flow / pressure be increased to max agreed.

However, at some discharge ports, this requirement of initial flow rate may be revised where line clearance/circulation techniques are employed.

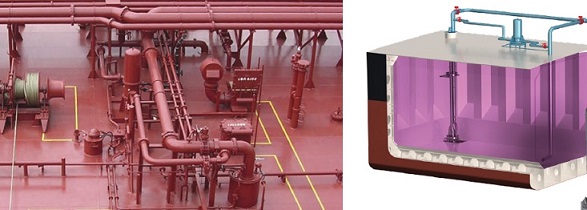

Standard Practice for Operating Centrifugal Cargo Pumps:

Centrifugal pumps are to be run at their full nominal RPM during bulk discharge. The reduction of RPM leads to a rapid decrease in pumping rate and pumping efficiency.

When the tank ullage is nearing low liquid levels, it is preferable to partially close the discharge valve, rather than reduce pump revolutions, to reduce the flow rate (to prevent cavitations, i.e., pump sucking gas at suction side due to vortex formation/gasification).

It is worth knowing that a 40% open butterfly valve will allow nearly the same flow rate as a 100% free butterfly valve. RPM may then be reduced as necessary

The use of the Auto Unloading System (AUS), where fitted shall be correctly and effectively utilized to reduce the overall discharge time.

Cavitations will occur when the pump tries to discharge more cargo than can enter the suction, i.e., with high viscosity cargo or where the shipment is highly volatile (high RVP cargoes). In such cases, the cargo tank I.G. pressure could significantly contribute to the increase of the cargo pump's NPSH (Net Positive Suction Head).

There is a danger of drawing gas or air instead of liquid into the pump, and the pump would then be operating in a partial vacuum instead of fluid.

Evidence of cavitations is increased vibration and reduced output, which will cause damage to the pump. Always watch the suction pressure gauge of the cargo pump.

During the pump operation, an officer must be on station at all times in the cargo control room to observe the tachometer and discharge pressure and be prepared to partially close ("throttle") the pump discharge valve if the pressure falls off or to shut down the pump if it loses suction

Precaution while operating Multi numbers of Cargo Oil Pumps:

It is essential to run all pumps at a similar pumping condition (Speed & Delivery Pressure).

If one pump runs much slower than others or much lower delivery pressure, it may stop pumping and heat up, possibly to a dangerous level. If there is high backpressure, it is doubtful whether it is worth running all pumps. Due to upper shore backpressure, a pump running at reduced RPM may not be discharged; therefore, energy is converted to the heat and could be dangerous.

Shutting Down of Cargo Pumps:

The pump discharge valve should be closed at the same time as the pump RPM's are reduced. When the pump has stopped, the suction valve should be closed.

When pumps are kept on rolling RPM with the discharge valve shut, a careful watch should be maintained on the parameters and temperatures.

A lower RPM will generate lesser adverse effects. For prolonged periods, consider shutting down.

Recording during Discharging in Tanker Cargo Log Book:

Following items shall be recorded in Tanker Cargo Log Book hourly:

- Discharged Quantity (Rate) to compare it with that of the terminal side,

- The pumping performance record / pumping log shall be maintained correctly,

- the times corresponding to those times written in the port Log Book.

- Pump Pressure and RPM,

- Manifold Pressure / Temperature,

- Draft & Trim

- Monitor of levels in tanks not being discharged

- The Stress and Stability of the vessel

- Tank pressure

Charterers are not only concerned with a vessel's sea performance but also their pumping ability, and as a result, the duration of port stays. Therefore, an informative and complete record of the discharge operation must be able to refute any claims of poor pumping performance.

An informative and complete record of RPM, rates, pump discharge pressures and suction pressures as well as pressures shown on the gauges at the manifold/ships rail is required to be able to refute any possible claims of poor pumping performance.

Chief Officer’s Standing Order:

Cargo's plan & instructions from the Chief officer should be followed.

The chief officer shall give his written instructions to the duty officer in his rest time.

Stress monitoring and print-outs of intermediate conditions shall be recorded during regular cargo operation. Loading computer shall be updated hourly for conditions on board.

A comparison of real & calculated draft & trim shall be carried out to give proactive warning of any unplanned or unobserved deviation from the plan.

Crude Oil Washing

Carry out crude oil washing as per “Procedures for Crude Oil Operations”

when the tank to be washed reaches the planned condition.

Ballasting and De-ballasting

Fill tanks with ballast water according to the ballasting plan.

Consider the precautions decided for heated cargo discharge.

Notify the terminal of the matter before the start of ballasting.

As a company standard, to avoid the possibility of ballast overflow when alongside, BALLASTING LEVEL OF ANY TANKS (WHILE ALONGSIDE) SHALL NOT EXCEED 90% OF THE TANK'S CAPACITY. Such levels shall be marked near the ballast gauges and shall be conspicuously displayed in the control room.

Trim and Draft

As the operation progresses, checking water depth makes a stern trim so that ample trim, which is described in the COW manual, may be obtained when tank stripping starts.

Ensure the draft maintained, after allowing for tidal variation, is well within the limits of manifold/loading arms' height limitation. The vessel shall always be preserved well within the operating limits (envelope) of the shore arms.

Stripping cargo

In the last stage of discharging, drop the number and speed of main cargo pumps and gradually reduce the opening of delivery valves to change over to stripping. Stripping is conducted by the Auto Unloading System (AUS), Eductors, or Stripping pumps.

For further confirmation of effective stripping with remote suction pressure gauge, a closed system of manual sounding (dipping) of cargo tanks shall be done by the ship's crew to ascertain the sludge/oil condition of tank bottom.

Survey upon completion of discharge from tanks

(Dry certificate / ROB certificate):

The cargo tanks are to be gauged in the presence of the attending surveyor/berth master to confirm free from pumpable (liquid) cargo.

The vessel is to prepare dry certificate (or ROB certificate, if pumpable liquid), upon completion and the same shall be acknowledged from the attending official.

If an available copy of the surveyor's documents to be retained on board.

Any remaining Un-pumpable cargo (by vessel's fixed pumping systems), if found,

shall be documented with suitable remarks on the certificate.

The closed method of dipping such cargo tanks shall be followed.

Completion of Discharge

Close the manifold gate valves after confirming the completion of transferring oil to the terminal.

Upon completion of a dry survey by the terminal (receiving) side, drain hoses and arms at the manifold, and disconnect them.

Drain hoses and arms at the manifold. All manifold drain valves are to be operated under the Chief Officer; the duty deck officer must be stationed at the manifold and ensure that the correct valves are opened before confirming to the Chief Officer in the CCR that the valves are opened.

After draining all oil in pipelines, close tank valves, and vent valves. Ensure the connection is depressurized and isolated from the internal cargo tank I.G. pressure

All cargo in deck cargo lines should be dropped by gravity into a designated tank or tanks. Lines should not be dropped back to the pump room.

In parallel with draining work, measure the temperature and ullage in each tank to work out the loaded quantity.

On completion of gauging and sampling, all ullage ports, vapor locks, and any other tank openings should be confirmed closed.

Care should be taken to ensure that cargo lines do not become over-pressurized due to high ambient temperatures

The IGS recorder shall be switched on to record and monitor the cargo tanks pressure. It shall be suitably marked for details of Voyage Number, date, and time of turning on and corresponding present pressure.

This record shall be in continuous operation until the final discharge port.

Stopping Inert gas system

Adjust inert gas pressure in tanks, and stop the system when the pressure reaches

the prescribed value (usually 1,000 mmAq).

Related articles:

Basic procedure for pumproom management

Ship to ship transferring oil Basic procedure and guideline

Oil pollution control Oil tanker safety guideline

Oil pollution countermeasures Oil tanker safety guideline

Oil cargo loading Preparation and guideline

Safe stability guideline for oil tankers Learn basic procedure

Oil spillage prevention Oil tanker safety guideline

Disaster prevention in oil tanker Procedure and guideline

Acceptance / rejection of fuel in a quality dispute

Operational guideline during bunkering

Bunker fuel sulfer limit of 3.50 % - Fuel Oil Regulations Frequently asked questions

Ships bunkering guideline- planning, preparation, safety checks & confirmation

Bunkering arrangement and safety factors onboard

Bunkering safe procedure and detail guideline for ships

How to keep bunkering record ?

Precautions prior transferring fuel oil into storage tanks

Treatment of waste oil and oily bilge

Bulk liquid cargo handling - Ship to shore safety checklist

Procedure for oil tankers and how to maintain records

Acceptance or rejection of fuel oil

Heating of fuel oil storage tank

Fuel oil viscosity control

Ships bunkering guideline- planning, preparation, safety checks & confirmation

Tanker vessel safety guideline - inert gas system

Tanker vessel safety guideline - gas freeing procedure

Precautions prior entering freezing zone - Check items in oil tankers operation

Tanker vessel safety guideline Check items in oil tankers operation

Tanker vessel safety guideline - how to prevent oil spillage

Tanker vessel safety guideline - tank cleaning procedures

How to ensure safe working atmosphere onboard?

Related Information

General guidance for oil tankers

Tanker equipment and machinery

Pumproom procedure

Pumproom inspection for tankers

Treatment for waste oil or oily bilges

Oil pollution prevention method

General precautions for tankers

Tanker equipment and machinery

General guidance for oil tankers

Other info pages !

Ships Charterparties Related terms & guideline

Stevedores injury How to prevent injury onboard

Environmental issues How to prevent marine pollution

Cargo & Ballast Handling Safety Guideline

Reefer cargo handling Troubleshoot and countermeasures

DG cargo handling Procedures & Guidelines

Safety in engine room Standard procedures

Questions from user and feedback Read our knowledgebase

Home page

ShipsBusiness.com is merely an informational site about various aspects of ships operation,maintenance procedure,

prevention of pollution and many safety guideline. The procedures explained here are only indicative,

not exhaustive in nature and one must always be guided by practices of good seamanship.

Site Use and Privacy - Read our privacy policy and site use information.

//Home //Terms and conditions of use

Copyright © shipsbusiness.com All rights reserved.