Procedure for ECDIS Position Fixing, Monitoring Passage, ECDIS Alarms & Chart Corrections

When using paper charts, the need to plot positions at regular intervals keeps the navigator actively involved amidst monitoring the progress of the voyage. He is frequently required to look at the chart generally and quickly detect if the vessel is being set off the course towards danger. He will also be looking ahead to the next waypoint and noting any dangers that are close to the track.

With ECDIS, there is the risk of losing this high level of situational awareness as the navigator's role becomes increasingly passive. A glance at the ECDIS may be considered enough to note the vessel's position and whether or not the vessel is on the course line, but this is not sufficient to ensure the safety of the vessel, to confirm the integrity of the automated position fixing or to maintain awareness of hazards ahead.

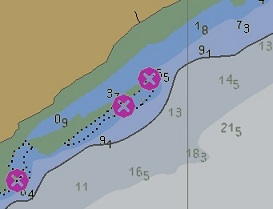

It is therefore essential that navigators maintain an active role and continueto manually plot positions at regular intervals to confirm the positiondisplayed on the ECDIS is correct. There have been cases of vessels running aground because the navigator did not notice that GPS positioning had been lost, and the ECDIS was running in DeadReckoningmode. A warning message should appear on the display when DR positioning is being used.

It is therefore essential that navigators maintain an active role and continueto manually plot positions at regular intervals to confirm the positiondisplayed on the ECDIS is correct. There have been cases of vessels running aground because the navigator did not notice that GPS positioning had been lost, and the ECDIS was running in DeadReckoningmode. A warning message should appear on the display when DR positioning is being used.